Following the bus stop design for Hanover, Peter Ruthenberg called one day on behalf of Heinrich Ganseforth, the Üstra chief, to ask if I would consider a bigger project, the design of the new tram for Hannover which was needed for Expo 2000 and to update the existing fleet of trams which had been designed in the 70s by Herbert Lindinger.

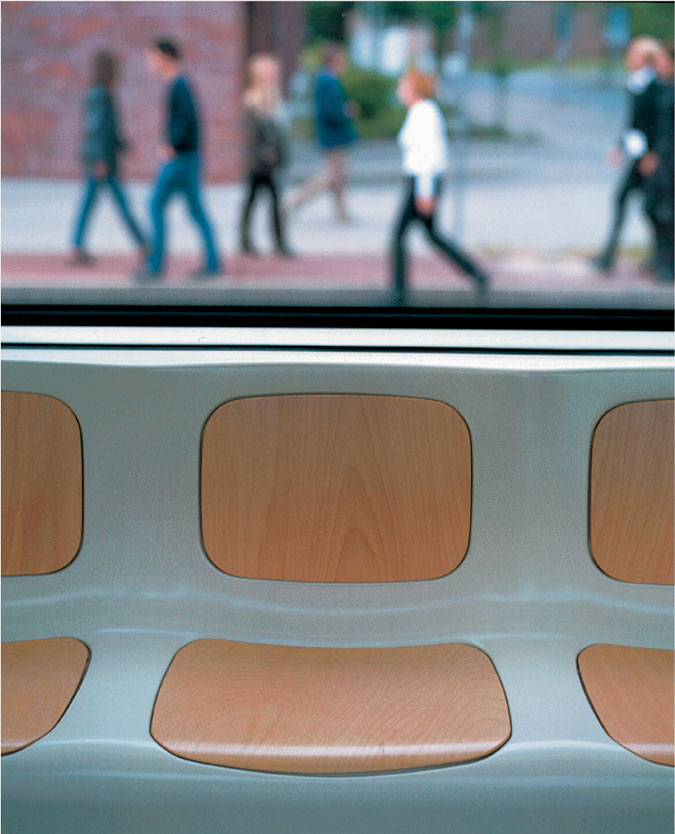

I was very unsure about handling a job of this scale but was persuaded to make a proposal and to take it step by step. We were a very small team, consisting of Colin Watson, Klaus Hackl and myself. Our approach was very simple: to design the tram for the passengers and to make every effort to make it something more enjoyable than a piece of civic equipment. I’d always loved London’s old double-decker bus, the Routemaster, which I think is still an unrivalled solution to urban public transport (with Venice’s vaporetto a close second perhaps) and much of the design thinking for the Hanover tram was measured against it.

We worked to a brief which had been developed by Üstra and Herbert Lindinger together with Linke Hoffmann Busch, the eventual manufacturer. I was lucky enough to find an Anglophile project leader at the tram factory, Alexander Friedrich, assisted by Klaus Bares and Klaus Hiller, and probably even luckier that it was his first tram project. Thanks to their willingness to do things differently and to work towards a great result, we achieved a lot more than we might have hoped for.

The development of the design was managed, in the end, by visits to the factory in Saltzgitter every ten days over a two year period. As the design progressed and manufacturing began (there wasn’t the time or the money for a prototype) these meetings began to be illustrated by the first trams on the production line, which would eventually spill one out every eight days. In these meetings we would negotiate with the various engineering groups to achieve what we considered the best solutions, balancing costs with achievable qualities. We worked on every visible detail, except for the graphics, which Bjorn Kussofsky did.

It was a well-timed diversion from the world of furniture and small things, and gave me the confidence to deal with more complex manufacturing situations. It was also a delight working with almost all of the engineers and others involved in the project, although at times the scale and responsibility of the project were hard to deal with.

Extracted from Everything but the Walls by Jasper Morrison (Lars Müller Publishers, 2006)